The Experience

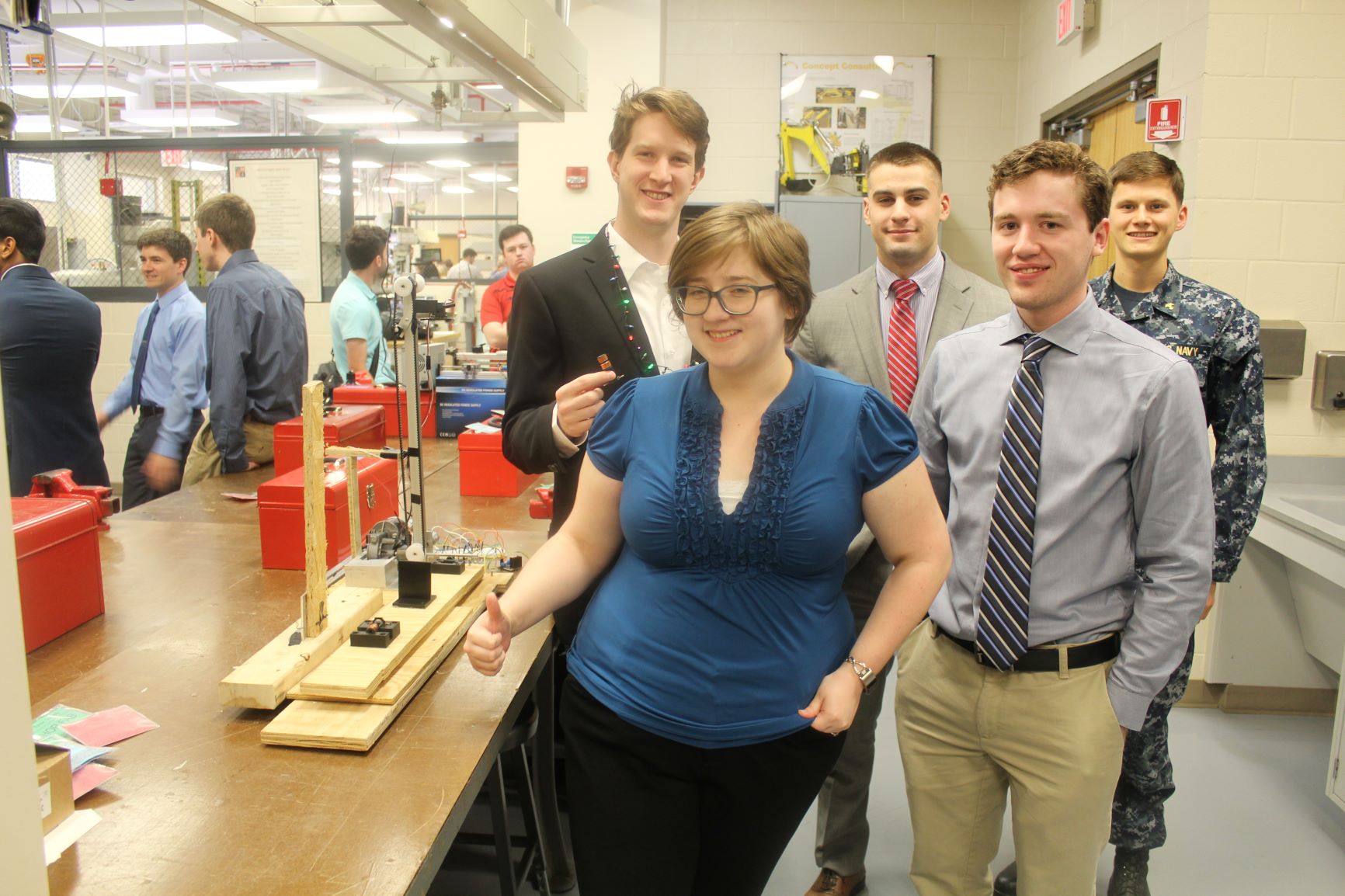

The ME Senior Design experience prepares students for the workplace through real world hands-on design/build experiences. The MAE 416 Capstone Design course involves a semester-long industry sponsored project for our mechanical engineering students.

Students leverage their technical and theoretical training, and apply it to the specifications and constraints imposed by the specific company project. Students learn to collaborate together on teams and report on their work both in writing and verbally in preparation for their future careers. They are required to research, plan, and prototype a solution to the industry problems. Each team is able to communicate with the “client” (company sponsor) during the semester to clarify the goals and scope of the project. The company engineers come to campus during the semester for several design reviews. At the end of the semester, the teams and companies come together for a 3-day event with sponsors, friends, and family to present and demonstrate their solution.

The Real-World Issues

This semester’s problem statements provided by our sponsors:

MAE 416-001 – Pool Cleaner Caddy

Users face difficulty in removing pool cleaners, due to their weight, after cleaning their pools. The purpose of this project is to develop a caddy prototype to retrieve and store the pool cleaners. The caddy should be compact, weighing less than 100 pounds and user friendly. It should be able to retrieve the cleaner in less than a minute.

MAE 416-002 – Heat Conduction System

The primary purpose of this senior design project is to develop a system that can isolate and determine the specific heat of an unknown substance for use in the NCSU MAE thermal fluids lab. This project focuses on the students’ learning experience by providing them with equipment that allows them to explore the different thermal properties of various fluids. The device must be able to reliably and accurately extract experimental information from a sample of a random fluid thus allowing the students to study its thermal properties. The system must be self-contained and function as a standalone device

MAE 416-003-Slip Ring Pick and Place

The primary purpose of this project is to design a machine to transfer slip rings onto alternator assemblies. Due to the need for faster manufacturing processes, Denso has tasked the students with creating a machine that is able to pick up a slip ring from one location and place it in the correct orientation 450 mm away. The design must also avoid a 55 mm obstruction in the middle of the path and be able to return to its start position within 12 seconds. When in operation, the machine should not pose any threat to nearby workers by having all forces limited to a maximum of 147 N and having no gaps less than 6 mm in width

MAE 416-004- Caterpillar Backhoe Loader Boom Lock Actuation System

The objective of this project is to improve Caterpillar’s backhoe loader boom locking system while maintaining quality and safety standards in a cost effective way. Currently, the system is comprised of two hooks actuated by a tensioned cable that locks the boom arm in place which is susceptible to supplier quality issues, adverse operating conditions, and operator error. The new design will provide a robust, modern solution that improves performance and reliability while ensuring safety.

MAE 416-005- Acoustic Isolation/Mitigation of ZURN’s VERDEdri Hand Dryers

The objective of this project is to enhance the current VERDEdri hand dryer to reduce the noise in the adjacent room by at least five decibels, as well as minimize noise in the surrounding area. Thin foam pads are installed inside the face plate of the dryer to mitigate noise and vibration, however, this current solution does not provide desirable sound damping. The hand dryer design improvements will provide a quieter hand drying experience for people in adjacent rooms, as well as the user, without diminishing the current capabilities of the hand dryer, thus enabling Zurn to promote a more competitive product.

Interested in sponsoring a team?

Becoming a senior design sponsor is rewarding for both you and the student team. A sponsorship is an opportunity to work with students who can analyze your proposal and provide a valuable solution.

For more information on sponsorship opportunities,

please contact: Mike Walsh | mpwalsh2@ncsu.edu | 919.515.7237