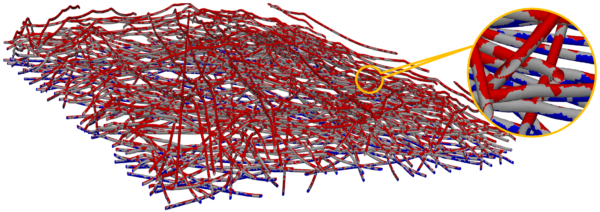

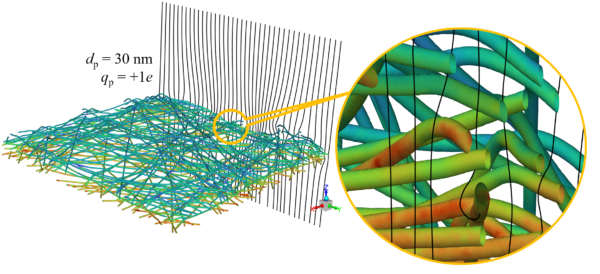

| Our research in this field is aimed at developing computational models (and corresponding experimental test setups) that allow one to optimize a filter’s microstructure. With such models the optimum fiber diameter(s) and their 3-D arrangements will be determined via 3-D numerical simulations for different flow and particle regimes. By controlling and optimizing the microstructure of a filter medium, one can control the filter’s particle collection efficiency (size-selective filtration) and minimize its pressure drop. Over the past decade, our group has developed unprecedented expertise in modeling aerosol filters. This includes, mathematical formulations and computer programs for modeling aerodynamic slip effects (the peculiar attribute that makes nanofibers better than their micron-sized counterparts for aerosol filtration), accurate particle tracking, and dust-cake formation to name a few. The figure below shows our first 3-D microscale (i.e., on scales comparable to fiber diameter) simulation of aerosol filtration in the absence of particle loading. This model was later enhanced to allow aerodynamic slip to occur at the surface of the nanofibers. |

|

Microscale simulation of aerosol flow through a fibrous sheet is shown in the figure to the left . Microscale simulation of aerosol flow through a fibrous sheet is shown in the figure to the left .

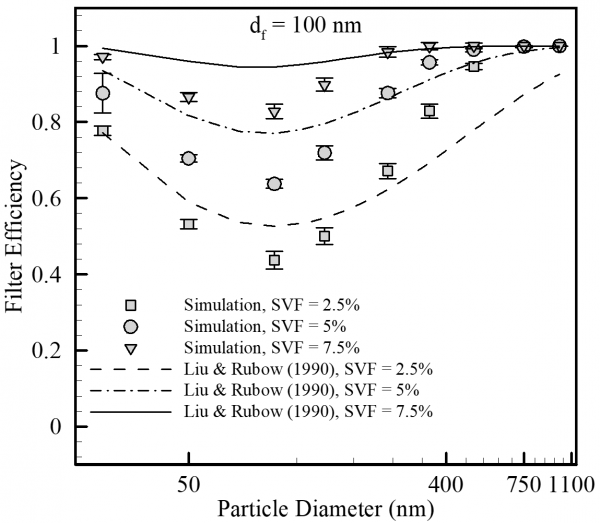

Comparison between our simulation data (symbols) and predictions of experimental correlations from literature are shown in the figure to the right. Note that no empirical factors where used to improve the simulation results [Hosseini and Tafreshi 2010]. Comparison between our simulation data (symbols) and predictions of experimental correlations from literature are shown in the figure to the right. Note that no empirical factors where used to improve the simulation results [Hosseini and Tafreshi 2010].

|

| Electrostatic Particle Capture

Electrostatic charge is a major part of modern-day aerosol capture that has remained poorly understood. We have conducted a series of numerical simulations to improve our understanding of how an electrostatically charged fiber captures airborne particles. Special attention was paid to the role of Coulomb and dielectrophoretic forces in the capture of particles of different charge polarities. |

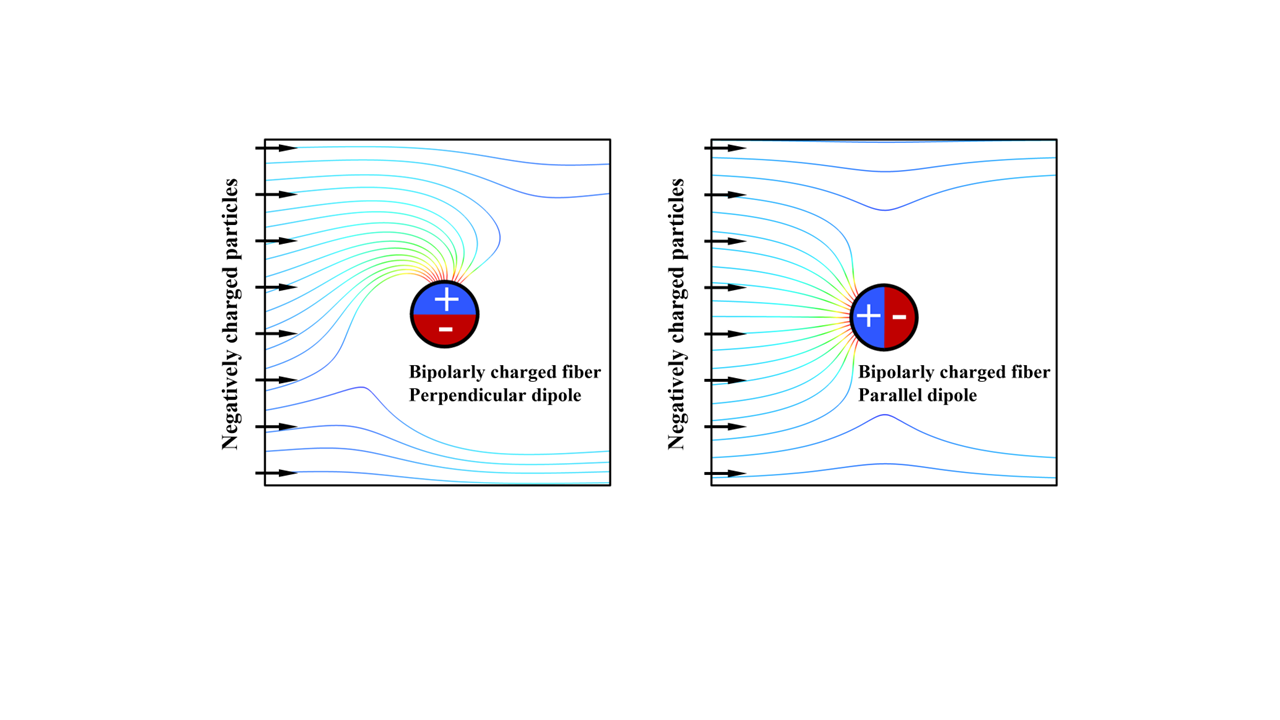

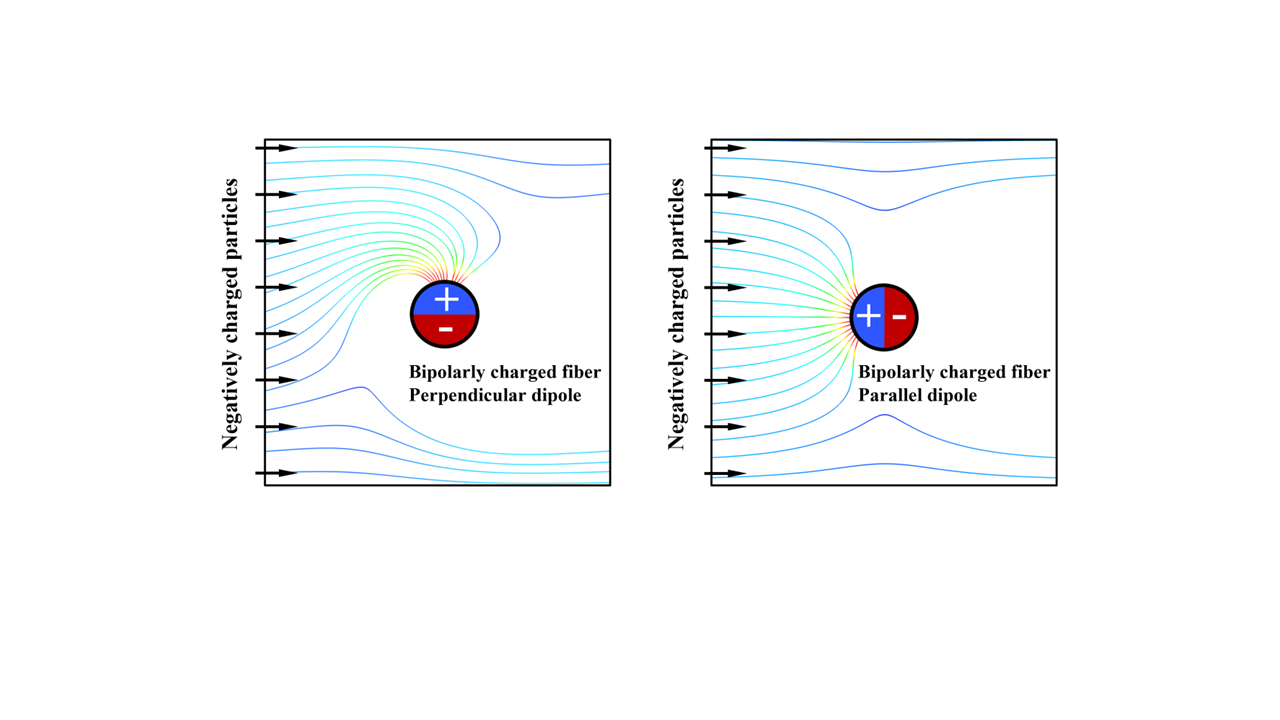

Trajectory of particles with a diameter of 300 nm carrying negative charges. The left figure shows a fiber with a dipole perpendicular to airflow direction. The figure to the right shows a fiber with a dipole parallel to airflow direction. Colors blue to red show particle velocity increasing as they get closer to the fiber. |

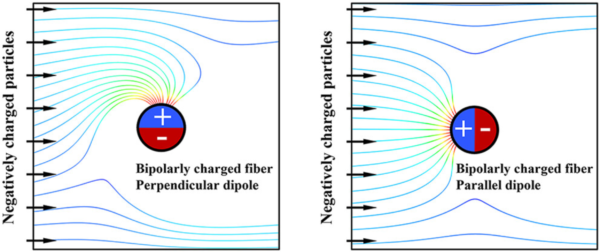

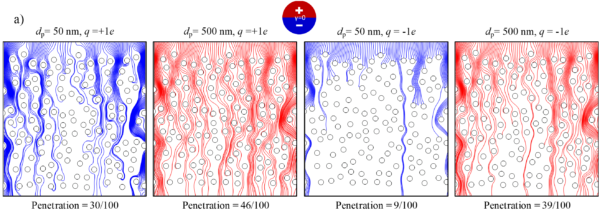

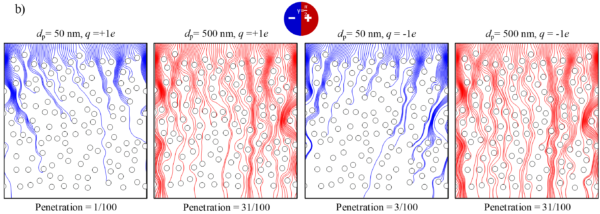

| The above concept was then used in a series of 2-D geometries comprised of randomly distributed fibers to study the impact of fiber dipole orientation on particle collection efficiency of a bipolarly charged filter (see the figure below). The highest and lowest efficiencies were observed for dipole orientations that were perpendicular and parallel to the airflow direction, respectively. The simulation results were also compared with the predictions of the popular semi-empirical correlations from the literature and good general agreement was observed, without the need for any empirical correction factors. |

Particle trajectories are shown for particles with diameters of 50 and 500 nm each having +1e charge (figures on the left) and -1e charge (figures on the right) for the case of parallel (a) and perpendicular (b) dipole orientations.

Electrostatic filtration efficiency vs. particle diameter for different dipole orientations are compared with one another for particles having the Boltzmann equilibrium charge. Predictions of the semi-empirical (cell-model-like) equations are also added for comparison. |

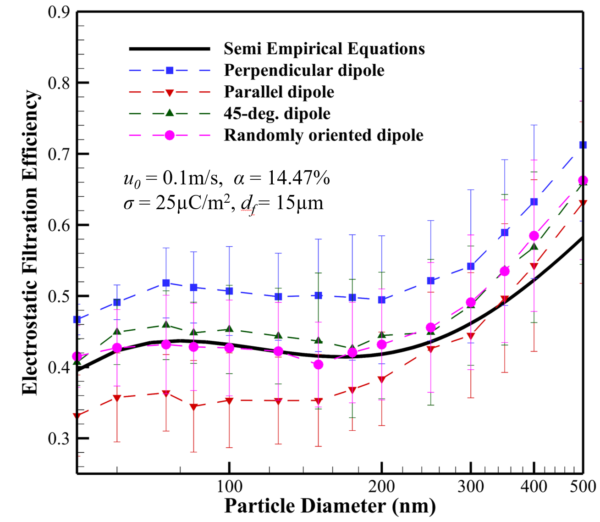

| We have also developed a simple computational model to simulate how different ways of corona-charging a filter can impact its aerosol collection efficiency. The model assigns different bipolar charges to the fibers in the media based on how the corona-generated negative ions impact these fibers they travel from the corona needles towards the grounded surface underneath the media. The charge assignment process is based on observations made from simulating the electrohydrodynamic field around the corona needles. |

A corona-charged virtual filter is shown in this figure with red, blue, and gray colors representing negatively charged, positively charged, and uncharged surfaces. |

| With the fibers virtually charged, the trajectory of positively and negatively charged aerosol particles, ranging in size from 30 to 1,500 nm, were simulated across the filter thickness to quantify the effect of fiber charge distribution on the filter efficiency. |

Particle trajectories (in the absence of Brownian diffusion) are shown for particles with a diameter of 30 nm and a charge value of 1e. The surface of the fibers is colored by the magnitude of the electrostatic force applied to the particle. Note how the particles are attracted to the downstream side of the fibers due to electrostatic forces. |

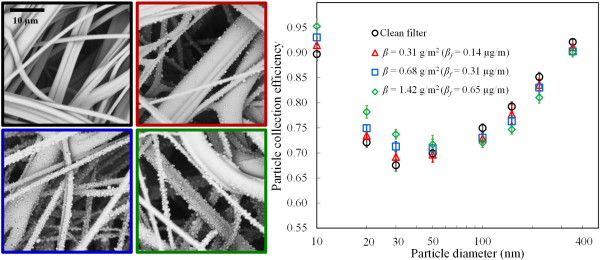

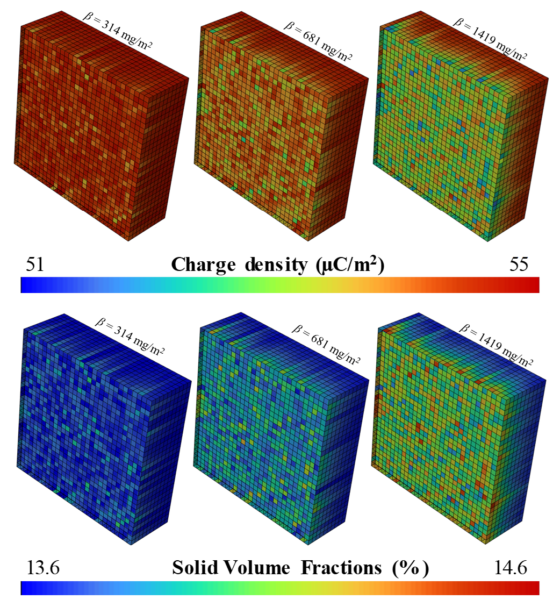

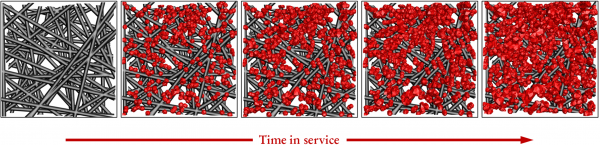

| Studies have shown that collection efficiency of an electrostatically-charged filter decreases with particle loading until the filter pores begin to be filled with particles and the particle collection efficiency starts to increase with further loading. combining numerical simulation and experiment, we developed a CPU-friendly model to formulate the impact of particle loading on filtration performance of charged filters.

|

Experimental results for the collection efficiency of an electrostatically charged polypropylene filter at various particle loadings. The frame color in the SEM images corresponds to the amount of mass loading given in the legends [Gautam et al. 2023].

The figure above is an illustration of charge shielding and neutralizations due to deposition of positive (blue) and negative particles (red) on a bipolarly charged fiber. Note the reduction of the fiber’s electrostatic field (green halo) due to particle deposition. The figure below (left) shows simulation results compared with experimental data for filter’s collection efficiency at various stages of loading. Filter’s charge density and particle-loaded solid volume fractions are shown for 3 different mass loadings in the figure below to the right [Gautam et al. 2023]. |

| We then developed a macroscale model to simulate the instantaneous collection efficiency and pressure drop of an electrostatically charged filter and calibrated the model using experimental data (see below). |

|

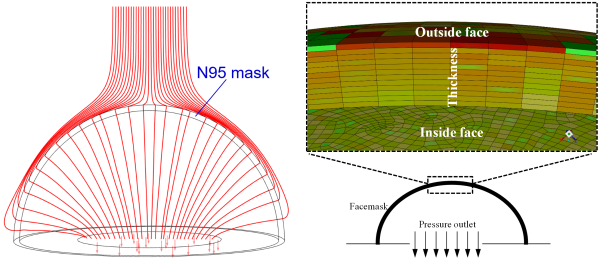

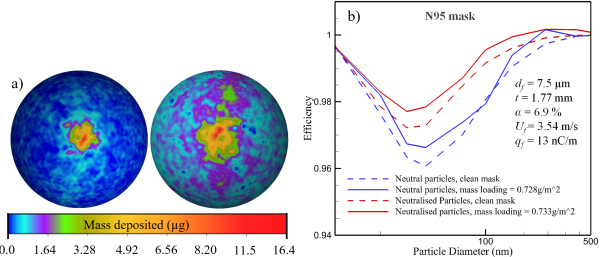

| The above-mentioned macroscale model was also used to simulate the instantaneous collection efficiency and pressure drop of an N95 face mask (see below) against neutral particles (having a zero-charge) as well as neutralized particles (having a Boltzmann or Fuch’s charge distribution). |

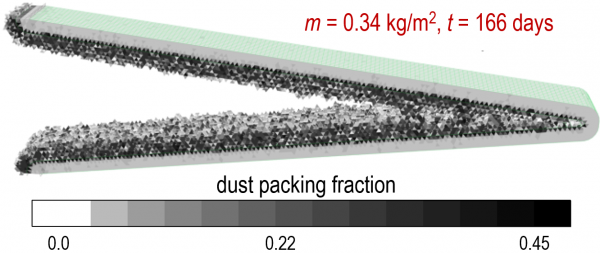

Air pathlines outside and inside the facemask are shown in a vertical plane that cuts through the mask (figure to the left). Note that air always enters the mask at a normal angle (minimum resistance path). A magnified cross sectional view of the mask under some particle loading is shown in the figure to the right. Colors from green to red show cell’s solid volume fraction from lowest to highest. Note that the cells on the outer face of the mask are more red than those on the inside face. Cells that have not received any particles have remained green [Jamali et al. 2023].

Contour plots of polydisperse mass deposition in N95 mask are shown in (a) for neutral nanoparticles (with a total mass per unit area of 3.87g/m2) and neutralized nanoparticles (with a total mass per unit area of 5.88g/m2). The total incoming mass in both cases were 7.4g/m2. Simulation results for collection efficiency of the N95 mask under nanoparticle loading in shown in (b) [Jamali et al. 2023]. |

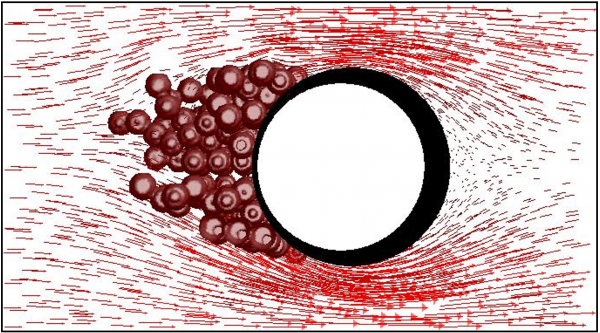

| The next step was to develop a microscale model for the inclusion of particle loading as part of the simulations. This allowed us to quantify the impact of particle dendrite formation on the collection efficiency and pressure drop of a filter, as shown below. |

Microscale simulation of particle deposition on a fiber (figure to the left) [Hosseini and Tafreshi 2012] and on a 3-D fibrous filter media (figure to the right) [Saleh et al. 2013]. |

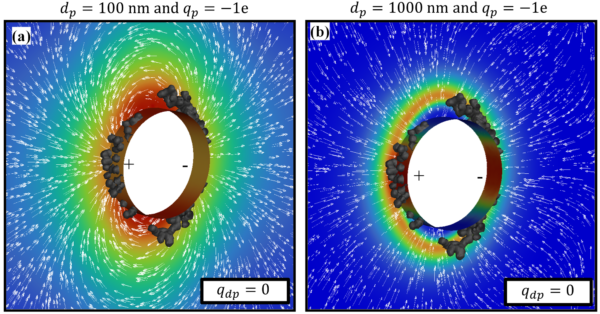

| The above microscale particle loading model was then extended to also include the effects of particle charge on the electrostatic field of a bipolar fiber (see bellow) |

The net electrostatic force (Coulomb + Polarization) experienced by the particles of diameter 100 nm and 1000 nm carrying a charge value of -1e in a particle loaded single fiber is shown. The fiber is loaded (mp= 1.5 µg/m) with particles of charge value qp= 0e (neutral particles) in (a) & (b). |

| We have also developed a fast and flexible algorithm to simulate the microstructure of 3-D assemblies of deformable particles of arbitrary shapes (see below). This structure-generation algorithm was also used to simulate how performance of an electrospun fibrous filter media can be improved by embedding spacer microspheres between the fibers. Such spacer particles can increase the porosity of the media and thereby improve the overall figure of merit (collection efficiency per unit of pressure drop) of the filter. |

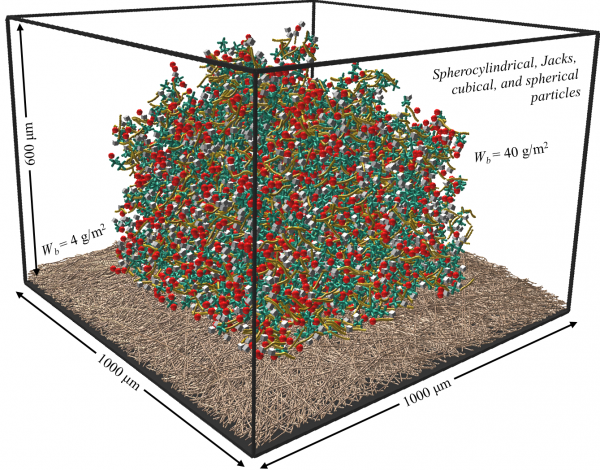

This figure shows an example of our polydisperse dust-cake simulations comprised of spherical (20 μm in diameter), cubical (aspect ratio 1), Jacks (aspect ratio 3), and spherocylinderical (aspect ratio 10) particles. The bead diameter used to create the cubical, Jacks, and spherocylinderical particles is 6 μm. The overall basis weight of the dust-cake is 40 g/m^2 with about 10 g/m^2 for each particle type. The fibrous filter media underneath the cake is made of fibers with a diameter of 3 μm and has a basis weight of 4 g/m^2 [Yousefi and Tafreshi 2020a].

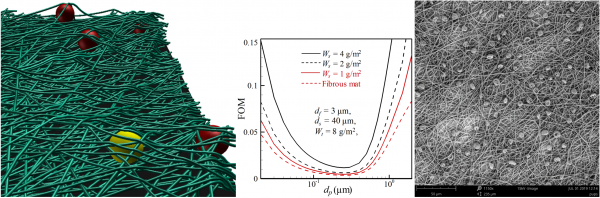

Polystyrene (PS) beads can serve as spacer particles to increase the porosity (and therefore filtration efficiency) of an electrospun fibrous (PU here) media. The figure on the left shows an example of our spacer-embedded fibrous structures generated used for the study. The SEM image on the right shows an PS-embedded electrospun Polyurethane fibermat. The middle figure shows the Figure of Merit (FOM) for an electrospun PU mat embedded with PS particles having different basis weights. The diameter of the PU fibers and PS beads are 3 and 40 micrometers, respectively [Yousefi and Tafreshi 2020b]. |

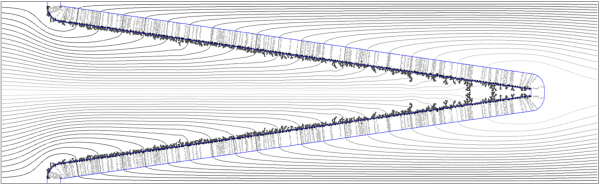

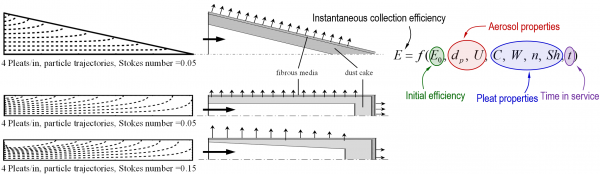

| We also developed a macroscale (i.e., on scales comparable to filter pleat size) simulation method to allow simulation of a complete filters (a pleated filter) under duct loading conditions with a reasonable CPU time in 2-D and 3-D (see below). To further speed up the design process, we derived a series of first-principle analytical expressions that can be used to predict the instantaneous pressure drop and collection efficiency of pleated filters under dust loading conditions. Both the depth and surface filtration regimes are formulated for filters with triangular and rectangular pleats (see the figure below). These expressions are specifically derived for the early stages of designing a pleated filter (prior to clogging) to circumvent the need for conducting CPU-intensive numerical calculations (see Saleh et al. 2016 for more details). |

Macroscale simulation of particle deposition inside (depth filtration) and on the surface (surface filtration) of a pleated filter in 2-D [Fotovati et al. 2012] and in 3-D [Saleh et al. 2014].

Analytical formulations to predict the performance of dust-loaded pleated filters [Saleh et al., 2016]. |

Representative Publications:

- S.A. Hosseini and H.V. Tafreshi, 3-D Simulation of Particle Filtration in Electrospun Nanofibrous Filters, Powder Technology 201, 153-160 (2010)

- S.A. Hosseini and H.V. Tafreshi, Modeling Particle-Loaded Single Fiber Efficiency and Fiber Drag using Fluent CFD Code, Computers and Fluids 66, 175 (2012)

- S. Fotovati, H.V. Tafreshi, and B. Pourdeyhimi, Unsteady–State Modeling of Depth Deposition in Pleated Aerosol Filters, Separation and Purification Technology 98, 344 (2012)

- A.M. Saleh, S.A. Hosseini, and H.V. Tafreshi, and B. Pourdeyhimi, 3-D Microscale Simulation of Dust-Loading in Thin Flat-Sheet Filters, Chemical Engineering Science 99, 284 (2013)

- A.M. Saleh, S. Fotovati, H.V. Tafreshi, and B. Pourdeyhimi, 3-D Modeling of Surface and Depth Particle-Loading in Pleated Filters, Powder Technology 266, 79 (2014)

- A.M. Saleh, H.V. Tafreshi, and B. Pourdeyhimi, An Analytical Approach to Predict Pressure Drop and Collection Efficiency of Dust-Load Pleated Filters, Separation and Purification Technology 161, 80 (2016)

- S.H. Yousefi and H.V. Tafreshi, Novel Approach to Model Microstructure of Dust-Deposits Comprised of Polydisperse Particles of Arbitrary Shapes, Separation and Purification Technology 244, 116844 (2020a)

- S.H. Yousefi and H.V. Tafreshi, Modeling Electrospun Fibrous Structures with Embedded Spacer Particles: Application to Aerosol Filtration, Separation and Purification Technology 235, 116184 (2020b)

- M. Jamali, S. Atri, S. Gautam, A.M. Saleh, H.V. Tafreshi and B. Pourdeyhimi, Macroscale Modeling of Electrostatically Charged Face Masks, Aerosol Science and Technology 57, 7, 700 (2023)

- S. Gautam, A.M. Saleh, H.V. Tafreshi, J.G. Radney, and B. Pourdeyhimi, Macroscale Simulation of Particle Loading in Electrostatically Charged Filters, Journal of Aerosol Science 173, 106212 (2023)

- S. Gautam, A. Kumar, H.V. Tafreshi, and B. Pourdeyhimi, A Simple Approach to Simulate Corona-Charged Electret Filters, Journal of Aerosol Science 176, 106293 (2024)

- A. Kumar, S. Gautam, S. Atri, H.V. Tafreshi, and B. Pourdeyhimi, Importance of Dipole Orientation in Electrostatic Aerosol Filtration, Langmuir 39, 17653 (2023)

Click here for a more complete list of publications |

Acknowledgement:

- The Nonwovens Institute,

- National Science Foundation (Nanomanufacturing program)

- National Institute of Standards and Technology (NIST –NIIMBL)

- NC Collaboratory Business–Academia Partnership Program

- Advanced Functional Fabrics of America (AFFOA, DOC)

|