Desalination Fibrous Membranes

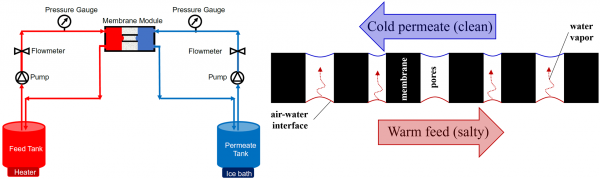

| Accessible fresh water is a global concern that is expected to worsen as the impact of global warming on our planet becomes more severe in the next decades. With a modest amount of energy, direct-contact membrane distillation (DCMD) can produce freshwater by creating a temperature difference between the feed (warm salty water) and permeate (cold purified water) separated from one another by a hydrophobic membrane. The temperature difference across the membrane creates a vapor pressure gradient that serves as the driving mechanism for the transport of water vapor from the feed to the permeate through the pores of the membrane (see the figure below). Mass transfer through a DCMD membrane is directly related to fresh water production rate and should be maximized, while heat transfer should be minimized to maintain a temperature difference across the membrane. |

Schematic of a direct contact membrane distillation (DCMD) is shown in the figure on the left. Flow on both sides of an DCMD membrane is shown schematically in the figure on the right [Ullah et al., 2018]. Schematic of a direct contact membrane distillation (DCMD) is shown in the figure on the left. Flow on both sides of an DCMD membrane is shown schematically in the figure on the right [Ullah et al., 2018]. |

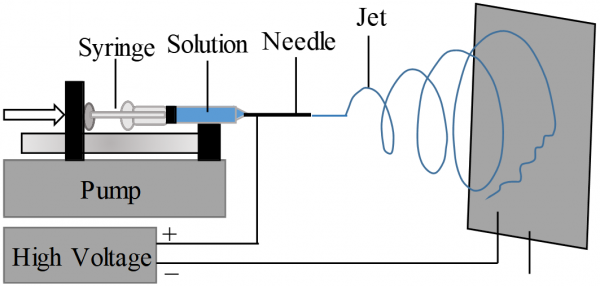

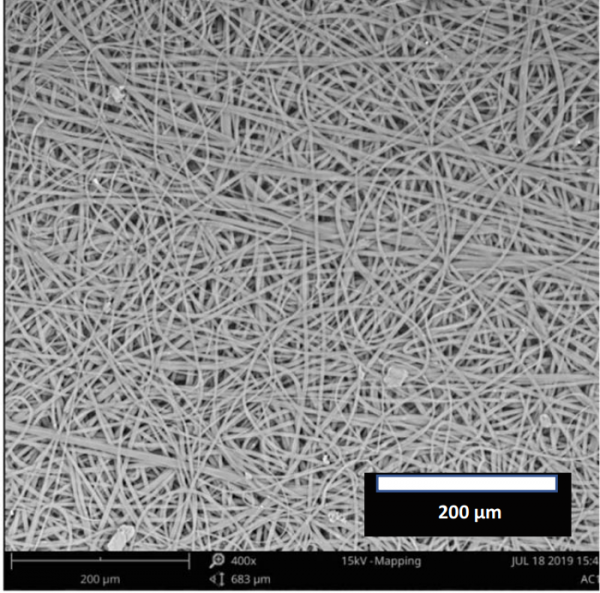

| While majority of existing membrane are produced as porous films, electrospinning is also becoming a method of membrane production for its unique microstructural attributes. |

The figure shows a schematic drawing for the electrospinning unit used to produce polystyrene membranes (the SEM image) used for desalination experiment [Esteves et. al., 2020 and Abdelrazeq et. al., 2020]. |

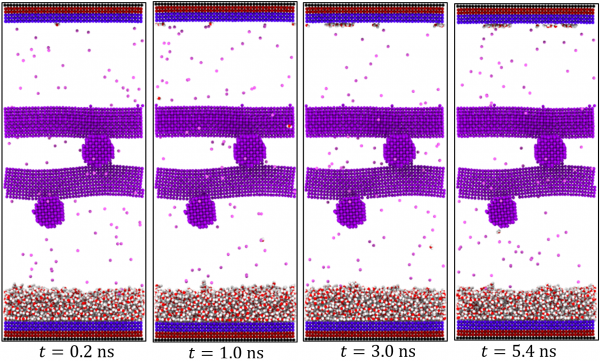

| This classical approach for modeling the perfromance of an DCMD membrane relies on predetermined empirical factors/relationships that compensate for the inaccuracies in the existing models as they fail to incorportae the microstructure of the membranes. To overcome these limitations we have considered a new modeling approach in which the membrane microstructure is used in the calculations. Such a computational tool can help one to predict the rate of heat and mass transport through a DCMD membrane from first principles rather than trial-and-error. Such simulations can be used to study the importance of membranes’ microstructure without the need for empirical correction factors. More specifically, the effects of fiber diameter, membrane porosity, and membrane thickness are simulated. |

Molecular Dynamics simulation of direct contact membrane distilation (in of a simplified fibrous membrane) showing the evaporation of water molecules from the warm feed side (the lower side) toward the cold permeate side (the upper side). Note the condensation on the permeate side [Hemeda et. al., 2018]. Molecular Dynamics simulation of direct contact membrane distilation (in of a simplified fibrous membrane) showing the evaporation of water molecules from the warm feed side (the lower side) toward the cold permeate side (the upper side). Note the condensation on the permeate side [Hemeda et. al., 2018]. |

Representative Publications:

|

Acknowledgement:

|