Droplet-Fiber Adhesion

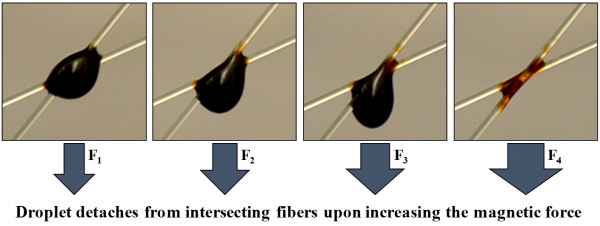

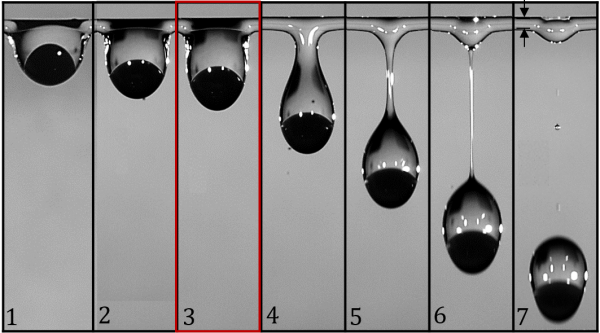

| Determining the force required to detach a droplet from a fiber or from an assembly of fibers is of great importance to many applications such as droplet-gas or droplet-liquid separation. We have developed a novel technique to measure this force experimentally by using ferrofluid droplets in a magnetic field (see Video 1 and Video 2 given below). This method allows one to isolated and study the effects of capillarity on the droplet–fiber adhesion. |

|

Video 1: Magnetic Detachment of a Ferrofluid Droplet from a Fiber Video 2: Magnetic Detachment of a Ferrofluid Droplet from Intersecting Fibers |

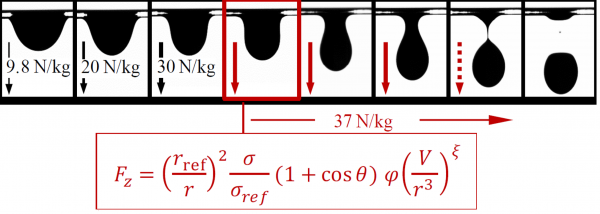

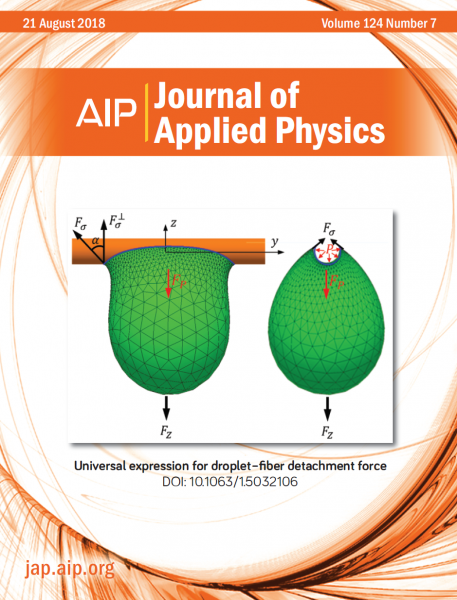

| Our study started with proposing a series of expressions to relate droplet detachment force to its geometrical dimensions at the moment of detachment (at the final equilibrium state before spontaneous detachment). To circumvent the need for conducting experiments or computer simulations to obtain these geometric dimensions, we developed a mathematical relationship that uses an existing set of detachment force data, obtained for an arbitrary droplet–fiber system, to predict the force of detachment for the droplet–fiber system at hand. To further facilitate the use of the above relationship, we used our own data to create an easy-to-use correlation for detachment force. This semi-empirical correlation can be used universally for droplet detachment force prediction without the need for running an experiment or a computer simulation for YLCAs greater than about 20. |

Combining the results of numerical simulation and experiment, we developed a universal expression that can be used for droplet detachment force prediction without the need for running an experiment or conducting a computer simulation [Farhan and Tafreshi 2018]. |

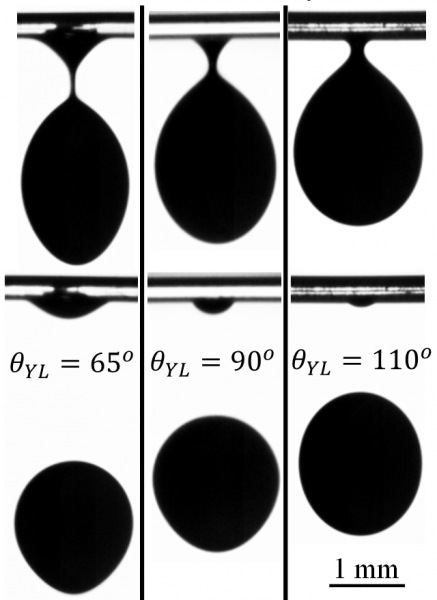

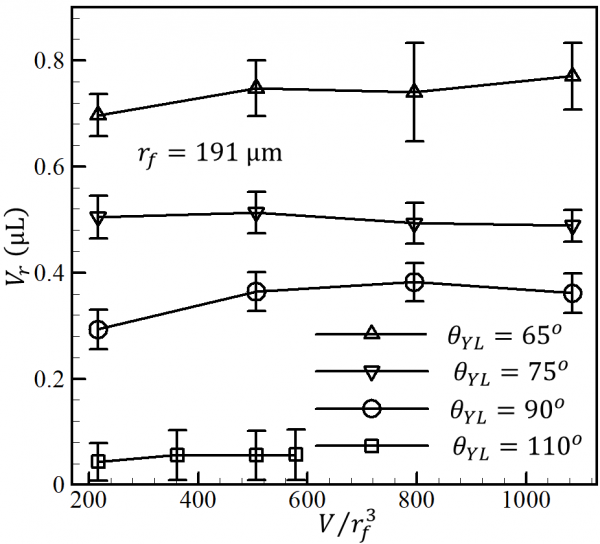

| The same experimental approach allows us to study the role of Young–Laplace contact angle (YLCA), fiber diameter, fluid viscosity, or droplet size on the volume of fluid residue left on the fiber after droplet detachment. Figure below shows the volume of the fluid residue on fibers with different YLCAs for droplets of different volumes. |

Example images of a droplet with a dimensionless volume of 506 detaching from a fiber with a radius of 191 μm but with different YLCAs are shown. Droplet residue volume left on the fibers is obtained via image processing and plotted for droplets of different dimensionless volumes [Aziz et al., 2018 and Jamali and Tafreshi 2021a]. |

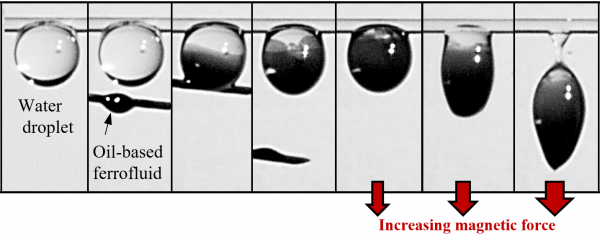

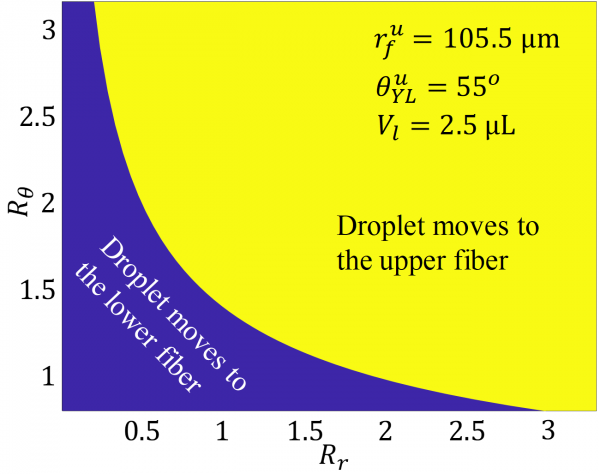

| We also established a method to use a magnetic force to measure the force of detachment for a nonmagnetic droplet from a fiber, for the first time. This was accomplished by adding a small amount of ferrofluid to the original nonmagnetic droplet. Depending on its surface tension relative to that of the nonmagnetic droplet, the ferrofluid may nest inside the nonmagnetic droplet or cloak it, as can be seen in the videos given below. |

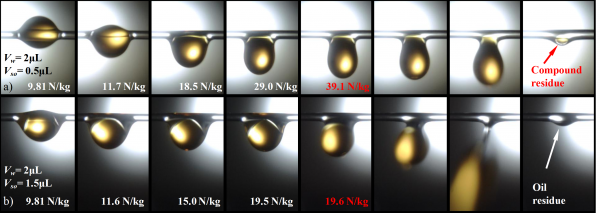

Example images of detaching compound droplets from a fiber a using a magnetic field. The figures on the left show a silicone droplet compounded with a nesting water-based ferrofluid droplet. The figures to the right show a water droplet compounded with a cloaking oil-based ferrofluid droplet [Farhan and Tafreshi 2019]. Video 3: Magnetic Detachment of a Non-Magnetic Droplet from a Fiber via Nesting Video 4: Magnetic Detachment of a Non-Magnetic Droplet from a Fiber via Cloaking |

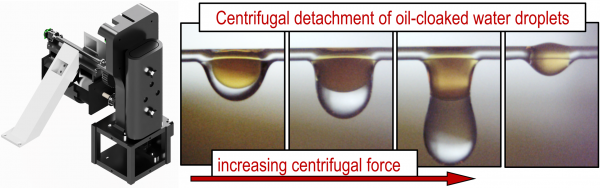

| To study the detachment of compound droplet (e.g., droplets comprised of two immiscible liquids like oil and water) from a fiber, we recently designed and built a device for centrifugal detachment of a droplet from a fiber. This device allows us to measure the force required to detach compound droplets of different compositions from a fiber and to also image them during the experiment (see the figures below). This research is aimed at improving the understanding of the interplay between the interfacial and external forces acting on a compound droplet during forceful detachment. The experiments were conducted using DI water for the primary droplet and silicone or mineral oil as the cloaking fluid. It was also found that that detachment force decreases with increasing the oil-to-water volume ratio (see Video 5 and Video 6 below). Our complementary numerical simulations also revealed the evolution of the interfacial forces between the phases under increasing external body force on the droplet, and allowed us to define effective interfacial tensions and contact angles for detaching droplets, for the first time. |

The figure on the left shows a schematic view of the centrifugal device built for our experiments. Side-by-side comparison between experimental and the computational results for a compound droplet on a fiber in the figures on the right. The figures in the upper row are for when the silicone-oil–water compound droplet is under gravity (barrel shaped configuration) and those in the lower row are for when the droplet is under critical acceleration [Holweger et al. 2021].  In-situ images taken from a water–silicone oil compound droplet during centrifugal detachment are shown in (a) for a silicone oil volume of 0.5 µL and in (b) for a silicone oil volume of 1.5 µL. The water droplet volume is 2 µm in both cases. Note that droplet detachment takes place at a lower body force in (b). Note also that some water residue is left on the fiber in (a) but not in (b) [Holweger et al. 2021].Video 5: Centrifugal Detachment of a Compound Droplet Comprised of Water and Silicone Oil In-situ images taken from a water–silicone oil compound droplet during centrifugal detachment are shown in (a) for a silicone oil volume of 0.5 µL and in (b) for a silicone oil volume of 1.5 µL. The water droplet volume is 2 µm in both cases. Note that droplet detachment takes place at a lower body force in (b). Note also that some water residue is left on the fiber in (a) but not in (b) [Holweger et al. 2021].Video 5: Centrifugal Detachment of a Compound Droplet Comprised of Water and Silicone Oil

Video 6: Centrifugal Detachment of a Compound Droplet Comprised of Water and Mineral Oil |

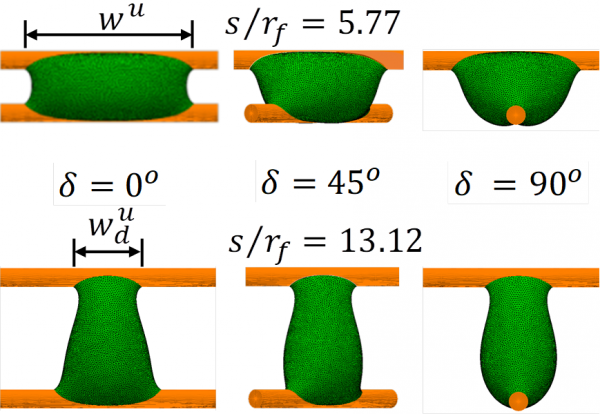

| Studying the mechanical forces acting on a liquid bridge between dissimilar fibers in parallel and orthogonal configurations, we formulated the contribution of geometrical and wetting properties of the fibers competing for the droplet that results from the liquid bridge breakup (see Video 7 and Video 8 below). We also developed an easy-to-use mathematical expression to predict the fate of this droplet. |

The figures on the left show the simulated 3-D shape of a liquid bridge between two fibers having different angles of 0, 45, and 90 degrees with respect to one another. The phase diagram on the right can be used to determine whether the droplet resulting from the breakup of a liquid bridge moves to the lower fiber or it moves to the upper fiber, when the fibers having different contact angles and diameters [Aziz and Tafreshi 2019]. |

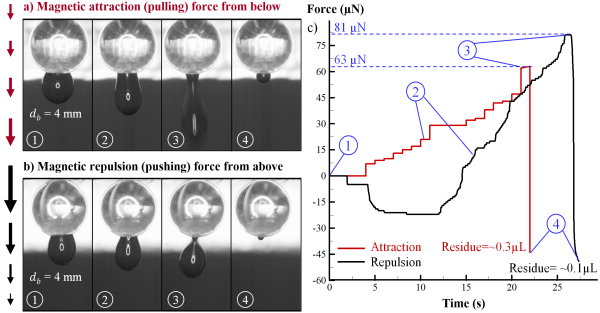

| We also demonstrated the possibility of using a magnetic repulsion force to reduce the volume of the residue that remains on a surface after detachment of a ferrofluid droplet. This technique provides a means for controlling the detachment residue by controlling the spatial strength of the magnetic field used for droplet detachment. The experimental technique developed in this work can help to improve our understanding of the underlying physics of droplet adhesion to a surface and the mechanics of residue formation during detachment (see the figure below). |

Snapshots from detachment of a 5 microliter ferrofluid droplet from a coated glass bead with a diameter of 4 mm via attraction (a) and repulsion (b) forces. Force trajectory vs time is shown in (c) for both experiments [Jamali et al. 2021]. Snapshots from detachment of a 5 microliter ferrofluid droplet from a coated glass bead with a diameter of 4 mm via attraction (a) and repulsion (b) forces. Force trajectory vs time is shown in (c) for both experiments [Jamali et al. 2021]. |

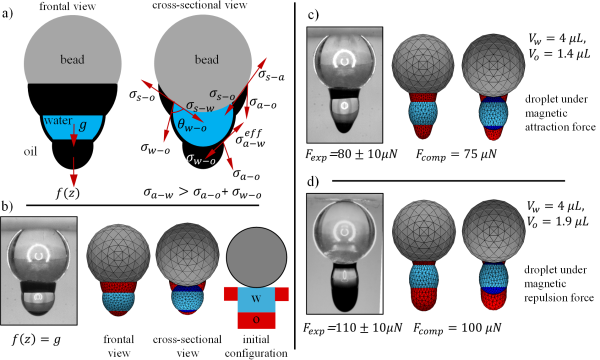

| We recently developed a new approach to simulate the 3-D shape of a droplet on a curved surface. The new approach circumvents the need for carrying out complicated derivations to obtain analytical expressions for the total energy of the interfacial areas between air, liquid, and solid surfaces. This approach also makes it easier to use Surface Evolver to model a two-phase droplet (e.g., a compound droplet) on a solid surface. To better illustrate our approach, the 3-D shape of single-phase and compound pendant droplets were simulated on a hydrophobic spherical surface in the presence of gravitational and magnetic fields (see the figure below). |

Schematic drawings for a water droplet fully cloaked (S<0) with an oil-based ferrofluid are shown in (a) from the frontal and cross-sectional views. Droplet shapes obtained experimentally and numerically are compared in (b), (c), and (d) under gravity, downward magnetic attraction force, and downward magnetic repulsion force, respectively. Colors light blue, red, and blue represent air–water interface, oil–air interface, and water–oil interface, respectively. Note that ferrofluid volume is different in each case [Jamali and Tafreshi 2021b]. |

Representative Publications:

|

Acknowledgement:

|