Tribology

Real-time Friction Error Compensation in Tube Hydroforming

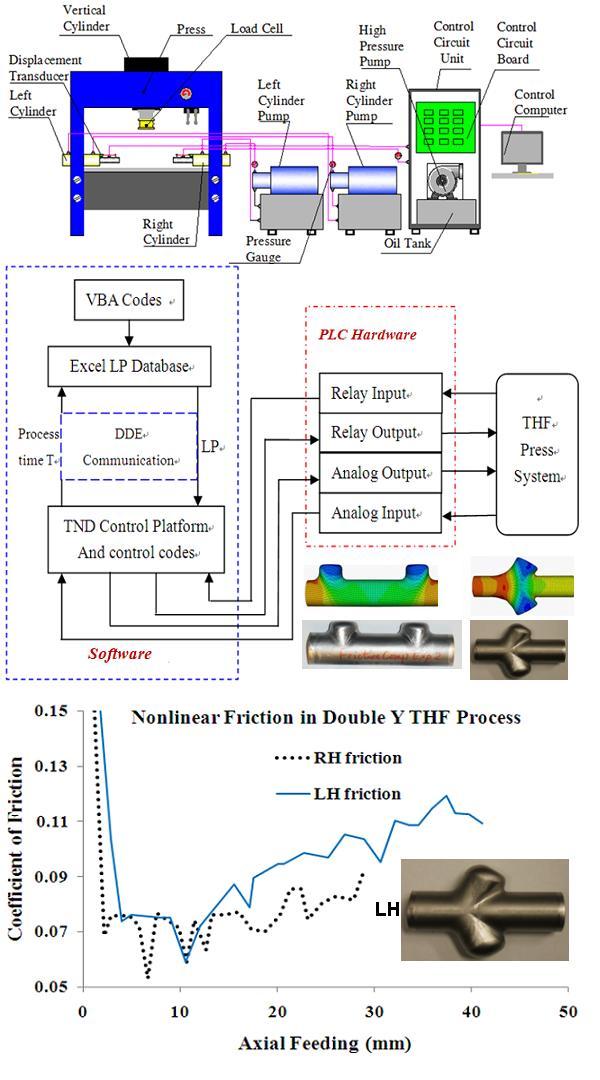

An algorithm and a software platform have been developed such that the sensed forming load from a THF machine is mapped to a database containing a set of loading paths that correspond to different friction conditions for a specific part. A real-time friction error compensation is then carried out by readjusting the loading path as the THF process progresses.

IMPACT:

- Real-time friction error compensation results in significant reduction in part failures caused by variability in the tribological conditions

- This procedure enhances part quality by acquiring uniform tube wall thickness