Hybrid Composites for Thermal Protection of CFRP

(Video link #2)

This project is to develop a hybrid multifunctional composite material that is an improvement upon the thermal and chemical stability, and surface durability of traditional polymer composites. Such hybrid multifunctional composite materials can be applied in higher temperature and harsher environment than current typical polymer based composites, and can be utilized especially in naval and marine parts for enhanced strength and durability (salty and high moisture environment).

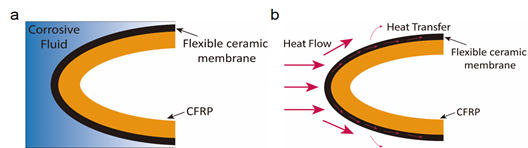

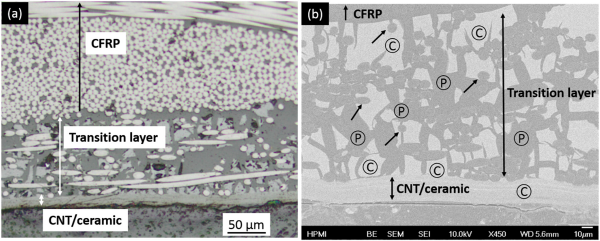

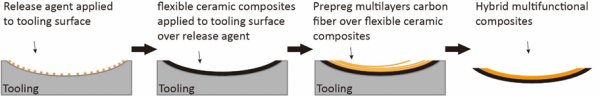

By using a standard co-curing lay-up process, in which a flexible conductive ceramic thin layer is bonded directly onto the outmost layer of polymer composites to ensure the material integrity, a new, effective and useful composite will be manufactured following the same procedure as standard carbon fiber reinforced polymer (CFRP) composites. In this way, a hybrid multifunctional composite material is created where the ceramic composite comprises the exterior layer of the material, for enhanced thermal/chemical stability and surface durability. Local environmental impacts (e.g., corrosive fluid and heat flow) will be quickly dissipated to surrounding area along the ceramic composite surface instead of penetrating or burning deeper inside the CFRP composite.

|

|

|

| Figure 1. (a) Hybrid multifunctional composite under corrosive fluid; (b) Hybrid multifunctional composite under heat flow. |

|

|

| Figure 2. (a) Optical and (b) backscattered electrons microcopy images of the cross-section of the hybrid ceramic-polymer composites. (arrow: cross-section of carbon fiber; C: ceramic matrix; P: polymer matrix.). |

Figure 3. The flexible conductive ceramic thin layer is bonded directly onto the polymer composites via the standard co-curing process. |