Fall 2017

Justin Morales is a Mechanical Engineering student with a focus in Material Science at Florida State University (FSU). He was awarded with the prestigious NASA NIFS opportunity (Internships, Fellowships & Scholarships) to work on a collaborative project between NASA Langley Research Center (LaRC) and Dr. Xu’s lab. The purpose of this project is to manufacture one kind of flexible, thermally-stable, radiation-shielding-capable ceramic composites for Mars exploration mission. Space is an extreme environment and NASA’s missions require advanced materials that can provide sufficient protection for space vehicles, structures, and astronauts.HOME

Our research interests include advanced manufacturing of multifunctional materials, sensor design and manufacturing in harsh environments, the electromagnetic spectrum, process optimization, sensor-based health monitoring and control through artificial intelligence (AI). Our research focus is on manufacturing of multifunctional ceramic materials, especially on their electrical/dielectric, mechanical, and thermal properties, and how to manufacture such materials for high temperature applications.

With unique properties such as high melting point, oxidation resistance, chemical and thermal stability, high hardness and strength, etc., ceramic materials are used extensively in extreme condition applications, such as hypersonic vehicles, turbines engines, power plants, and nuclear reactors. Such studies provide great flexibility in design and manufacturing and meet a wide range of application requirements, such as high temperature sensor design, electromagnetic (EM) absorption material, conformable patch antennas, high temperature radio frequency (RF) transparent materials, metamaterial designs for extreme condition applications, etc.

| NEWS |

Xu’s Recently Hosted Thermal Management Workshop Brings in 100+ Total Attendees!March 2024 Dr. Cheryl Xu, in collaboration with Dr. Weiming Lu from Collins Aerospace, recently hosted a Thermal Management workshop with the support of the American Carbon Society and North Carolina State University. The workshop brought together some of the brightest minds from government, industry, and academia to dive into the latest advancements and explore the future of high-temperature materials science. Through keynote speeches, panel discussions, poster sessions and hands-on lab tours, the event founded a strong understanding of the challenges and opportunities within thermal management, and fostered collaborations that will bridge the gap between theory and application. The workshop gathered significant attendance with over 45 in-person attendees and another 35 guests who joined virtually. An additional 30+ NCSU students gathered to present posters on their ongoing research as it relates to thermal management, contributing further to the enriching and valuable workshop experience.

|

Xu Invited to Serve as Editor-in-Chief for “Nature Portfolio”September 2023 Dr. Cheryl Xu was recently selected to serve as an Editor-in-Chief for Nature Portfolio’s well respected advanced manufacturing journal. Nature Portfolio is a well known organization in the scientific community that collaborates with scientists to publish high-quality open access research. They offer an expansive series of scientific journals in life sciences, health sciences, physical sciences, applied sciences, and society and the environment. As an Editor-in-Chief, Dr. Cheryl Xu will be collaborating with and supporting top academics in the field of advanced manufacturing to deliver their research to the global scientific community. |

Team Completes NSF National I-Corps Program and Wins ‘People’s Choice Award’August 2023 A team out of Dr. Cheryl Xu’s research group has recently completed the NSF National I-Corps Teams Program for the next generation stealth material they are developing. The team, led by entrepreneurial lead Jason Solomon and co-entrepreneurial leads Michael Reid and Parth Tulaparkar, traveled around the country completing 103 customer discovery interviews to assess the commercial viability of their technology. With the help of Office of Research Commercialization program manager Zachary Williams as the team’s industry mentor and principal investigator Dr. Xu as the technical lead, the team excelled throughout the I-Corps journey, which culminated in the team winning the ‘People’s Choice Award’ for best final presentation.

|

Xu Participates in NASEM Meeting of ExpertsMarch 2023 Dr. Cheryl Xu participated in “High Temperature Electromagnetic Materials: A Meeting of Experts”, hosted at the National Academies of Sciences, Engineering, and Medicine (NASEM) in Washington D.C. on March 2. She was invited by the Defense Materials, Manufacturing and Infrastructure (DMMI) Standing committee of NASEM to deliver her seminar, titled “Characterization of Material’s Electromagnetic (EM) and infrared (IR) Properties at High Temperature and Metamaterial Design Enabling Transparency”. |

NCSU Chancellor’s Innovation Fund on High Temperature Ceramic MaterialJuly 2021 Thanks to the Chancellor’s Innovation Fund (CIF), our project received support that could bring our research one step closer to market-ready technologies — with broad societal impacts. “Since the Chancellor’s Innovation Fund launched over a decade ago, it’s proven to be a highly effective way NC State can help our faculty commercialize their cutting-edge research — and ultimately solve pressing problems,” says Wade Fulghum, assistant vice chancellor of the Office of Research Commercialization. “The goal is to provide the critical funding needed to translate technologies to a point where a startup can be formed for commercialization or a license can be executed with an existing company.” |

How a Tougher Skin Could Change the Shape of AircraftMay 2021 The work to this point is described in a trio of papers published in the journal ACS Applied Materials & Interfaces: “Wide-Band Tunable Microwave-Absorbing Ceramic Composites Made of Polymer-Derived SiOC Ceramic and in Situ Partially Surface-Oxidized Ultra-High-Temperature Ceramics,” “Ultrahigh-Temperature Ceramic–Polymer-Derived SiOC Ceramic Composites for High-Performance Electromagnetic Interference Shielding,” and “Multifunctional Ceramic Composite System for Simultaneous Thermal Protection and Electromagnetic Interference Shielding for Carbon Fiber-Reinforced Polymer Composites.” |

Jin Choi selected as the 2021-2022 MAE Faculty Senior ScholarMay 2021 One rising senior per engineering department is selected for this honor each year. All the department nominees go on to interview for the COE Faculty Senior Scholarship. Jin is among one of them in the finalist. |

Dr. Xu Speaks With WIRED.com About AI in ManufacturingApril 2021 “At a Ford Transmission Plant in Livonia, Michigan, the station where robots help assemble torque converters now includes a system that uses AI to learn from previous attempts how to wiggle the pieces into place most efficiently”. “The technology allows this part of the assembly line to run 15 percent faster, a significant improvement in automotive manufacturing where thin profit margins depend heavily on manufacturing efficiencies”. |

Dr. Xu Named ASME FellowSeptember 2020 Dr. Cheryl Xu has been elected as an ASME Fellow, an honor bestowed to only 3% of its 100,000+ members. Fellow Grade is the highest elected grade of membership within ASME, the attainment of which recognizes exceptional engineering achievements and contributions to the engineering profession. |

3D-Printed Ceramic Sensors for Hypersonic VehiclesJuly 2020 Dr. Xu’s group has worked with the Air Force Research Laboratory to develop a way to 3D print sensors made of super-strong ceramics that can survive extreme temperatures and hypersonic velocities. For example, the strong sensors can be used in propulsion or thermal protection systems, leading edges of hypersonic vehicles, lightweight mechanical metastructures, or microelectromechanical systems. The technology of reinforced ceramics 3D printing of sensors uses a new liquid polymer in a 3D printer that can dispense pre-ceramic polymer, which is then pyrolyzed to form ceramic. Additive manufacturing opens up opportunities to capture the value of the materials, but with custom solutions to form and deliver in extremely short timelines. |

Dr. Xu’s Interview on AFOSR TwitterSummer 2019 Dr. Cheryl Xu @NCState stopped by during a visit to @AFOSR and shared how her experience with AFOSR funding has not only had an amazing impact on her career, but the careers of her students. @ncstatemae @AFResearchLab #BasicResearch #Grants #Funding #Careers |

Justin Selected with NASA NIFS Opportunity for Mars Mission |

News from the FSU 12th Annual Innovators’ ReceptionFall 2017 The Florida State University Offices of Research and Commercialization recognize the members of the university community who have achieved notable milestones in intellectual property and commercialization. Quotes from VP Dr. Gary Ostrander: “Your efforts to commercialize your research are enthusiastically applauded as it is no small task to first recognize the marketplace potential of your work, and then endure the highs and lows of its commercial journey. Each of you is an innovator in the truest form and FSU is fortunate to have access to your vision and expertise as we work together to improve the world.”

Photo taken with FSU President John E. Thrasher. |

Dr. Xu won GAP awards to take science from lab to market (Featured in FSU news)Summer 2017 Dr. Xu developed a novel sensor using ceramic material that can withstand harsh environments, such as the inside of a turbine engine located on a jet or in a power plant. These sensors can provide critical temperature and pressure data, alerting operators to potential problems before they occur. |

High Temperature Furnace Apparatus for Dielectric Property Characterization of Ceramic MaterialsSpring 2017 In order to measure the electrical properties of ceramic materials, an experimental apparatus has been designed and set up to measure the dielectric properties of ceramic materials at high temperature and in hostile environments, which is one of free space measurement (wirelessly non-contact non-destructive measurement). |

FSU Researchers Win GAP Awards to Launch Ideas to Marketplace (Featured in FSU News)Summer 2016 Dr. Xu is using a 3D printer to create a novel ceramic material that can withstand harsh environments, such as the inside of a high-speed jet turbine. The sensors can provide critical data about heat and pressure abnormalities occurring in the intricate spaces of these turbines that can help predict issues before they occur. |

Dr. Xu Selected as the 2015 Only Recipient of the IEEE Education Society Teaching AwardThe IEEE Education Society has selected Dr. Xu to be the 2015 recipient of the Mac E. VanValkenburg Early Career Teaching Award. On behalf of the IEEE Education Society, James (Jim) J. Sluss, Jr., Ph.D., President, IEEE Education Society, informed Dr. Xu of her selection as recipient of this award. “For leadership in engineering education innovation and outstanding classroom teaching, providing students with hands-on experience in classes and research, and helping them understand fundamentals using practical examples.” |

2011 ONR Young InvestigatorDr. Xu is among the 2011 ONR Young Investigator Awardees. |

2011 SME Outstanding Young Manufacturing EngineerThe Outstanding Young Manufacturing Engineer Award is to recognize manufacturing engineers, who have made exceptional contributions and accomplishments in the manufacturing industry. |

UCF Scientists Won Research Grant to Develop Power-Plant SensorFrom Orlando Sentinel, September 1, 2009: A trio of UCF scientists (Drs. Gong, An and Xu) has been awarded $811,186 by the U.S. Department of Energy to invent a tiny-but-tough device that could help solve global warming and reduce energy consumption. |

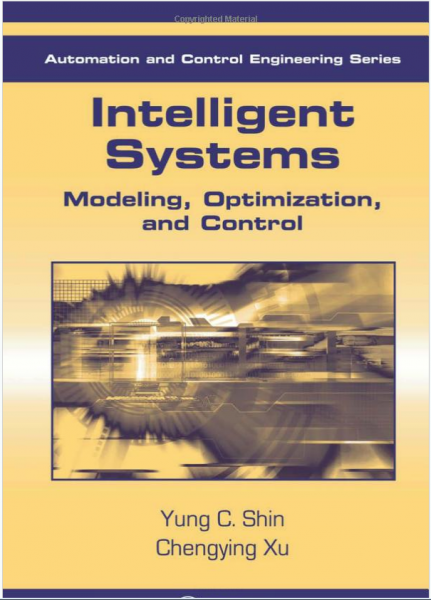

A Textbook: Intelligent Systems: Modeling, Optimization, and ControlA textbook “Intelligent Systems: Modeling, Optimization and Control” authored by Dr. Shin and Dr. Xu has been published in Jan. 2009 by CRC Press, Francis and Taylor Group. This book provides a thorough introduction in the field of artificial intelligence / soft computing / machine learning techniques. It covers every major technique in artificial intelligence in a clear and practical style.

|